An electrolytic capacitor is a

polarized capacitor

A capacitor is a device that stores electrical energy in an electric field by virtue of accumulating electric charges on two close surfaces insulated from each other. It is a passive electronic component with two terminals.

The effect of ...

whose

anode

An anode is an electrode of a polarized electrical device through which conventional current enters the device. This contrasts with a cathode, an electrode of the device through which conventional current leaves the device. A common mnemonic is ...

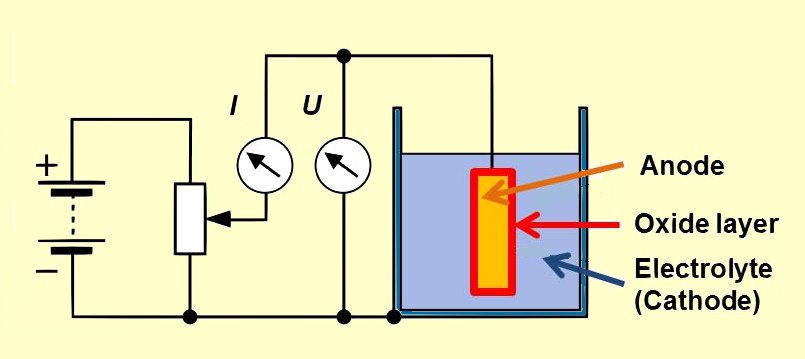

or positive plate is made of a metal that forms an insulating

oxide

An oxide () is a chemical compound that contains at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion of oxygen, an O2– (molecular) ion. with oxygen in the oxidation state of −2. Most of the E ...

layer through

anodization

Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts.

The process is called ''anodizing'' because the part to be treated forms the anode electrode of an electr ...

. This oxide layer acts as the

dielectric

In electromagnetism, a dielectric (or dielectric medium) is an electrical insulator that can be polarised by an applied electric field. When a dielectric material is placed in an electric field, electric charges do not flow through the mate ...

of the capacitor. A solid, liquid, or gel

electrolyte

An electrolyte is a medium containing ions that is electrically conducting through the movement of those ions, but not conducting electrons. This includes most soluble salts, acids, and bases dissolved in a polar solvent, such as water. Upon dis ...

covers the surface of this oxide layer, serving as the

cathode

A cathode is the electrode from which a conventional current leaves a polarized electrical device. This definition can be recalled by using the mnemonic ''CCD'' for ''Cathode Current Departs''. A conventional current describes the direction in whi ...

or negative plate of the capacitor. Due to their very thin dielectric oxide layer and enlarged anode surface, electrolytic capacitors have a much higher

capacitance

Capacitance is the capability of a material object or device to store electric charge. It is measured by the change in charge in response to a difference in electric potential, expressed as the ratio of those quantities. Commonly recognized are ...

-

voltage

Voltage, also known as electric pressure, electric tension, or (electric) potential difference, is the difference in electric potential between two points. In a static electric field, it corresponds to the work needed per unit of charge to m ...

(CV) product per unit volume than

ceramic capacitor

A ceramic capacitor is a fixed-value capacitor where the ceramic material acts as the dielectric. It is constructed of two or more alternating layers of ceramic and a metal layer acting as the electrodes. The composition of the ceramic material de ...

s or

film capacitor

Film capacitors, plastic film capacitors, film dielectric capacitors, or polymer film capacitors, generically called film caps as well as power film capacitors, are electrical capacitors with an insulating plastic film as the dielectric, sometime ...

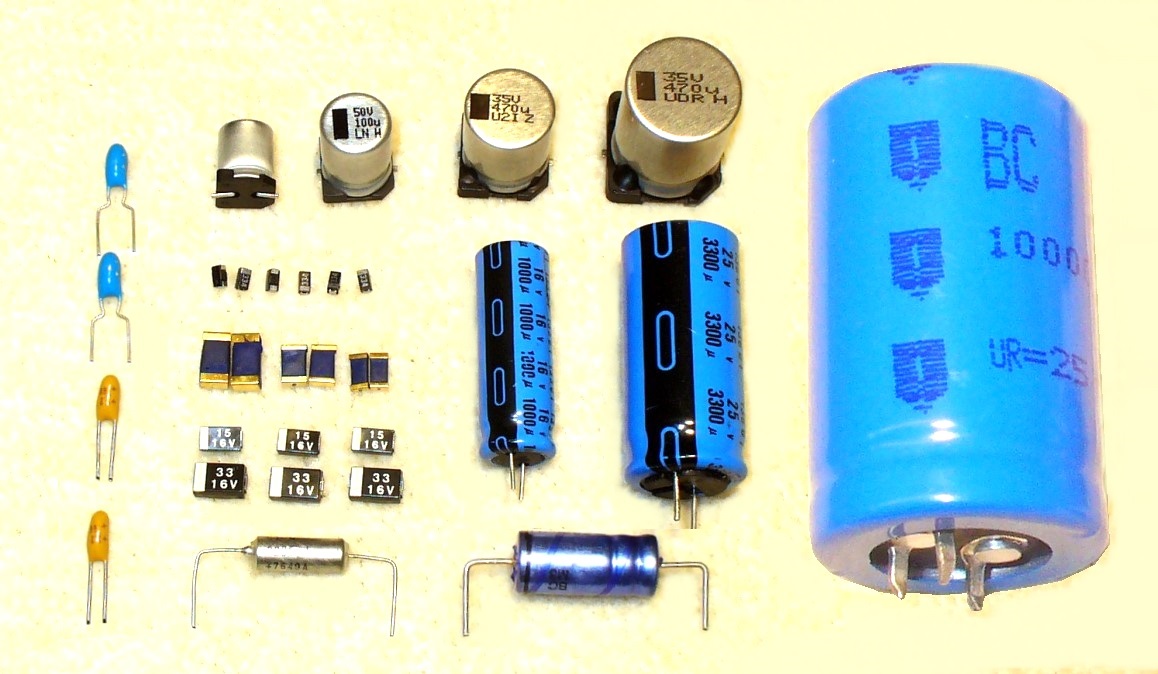

s, and so can have large capacitance values. There are three families of electrolytic capacitor:

aluminum electrolytic capacitor

Aluminum electrolytic capacitors are polarized electrolytic capacitors whose anode electrode (+) is made of a pure aluminum foil with an etched surface. The aluminum forms a very thin insulating layer of aluminum oxide by anodization that acts ...

s,

tantalum electrolytic capacitors, and

niobium electrolytic capacitors.

The large capacitance of electrolytic capacitors makes them particularly suitable for passing or bypassing low-frequency signals, and for storing large amounts of energy. They are widely used for decoupling or noise

filtering in

power supplies

A power supply is an electrical device that supplies electric power to an electrical load. The main purpose of a power supply is to convert electric current from a source to the correct voltage, current, and frequency to power the load. As a res ...

and DC link circuits for

variable-frequency drive

A variable-frequency drive (VFD) is a type of motor drive used in electro-mechanical drive systems to control AC motor speed and torque by varying motor input frequency and, depending on topology, to control associated voltage or current variat ...

s, for coupling signals between

amplifier

An amplifier, electronic amplifier or (informally) amp is an electronic device that can increase the magnitude of a signal (a time-varying voltage or current). It may increase the power significantly, or its main effect may be to boost the v ...

stages, and storing energy as in a

flashlamp

A flashtube (flashlamp) is an electric arc lamp designed to produce extremely intense, Coherence (physics), incoherent, full-spectrum white light for a very short time. A flashtube is a glass tube with an electrode at each end and is filled with ...

.

Electrolytic capacitors are polarized components due to their asymmetrical construction and must be operated with a higher potential (ie, more positive) on the anode than on the cathode at all times. For this reason the polarity is marked on the device housing. Applying a reverse polarity voltage, or a voltage exceeding the maximum rated working voltage of as little as 1 or 1.5 volts, can destroy the dielectric and thus the capacitor. The failure of electrolytic capacitors can be hazardous, resulting in an explosion or fire. Bipolar electrolytic capacitors which may be operated with either polarity are also made, using special constructions with two anodes connected in series. A bipolar electrolytic capacitor can also be made by connecting two normal electrolytic capacitors in series, anode to anode or cathode to cathode.

General information

Electrolytic capacitors family tree

As to the basic construction principles of electrolytic capacitors, there are three different types: aluminum, tantalum, and niobium capacitors. Each of these three capacitor families uses non-solid and solid manganese dioxide or solid polymer electrolytes, so a great spread of different combinations of anode material and solid or non-solid electrolytes is available.

Charge principle

Like other conventional capacitors, electrolytic capacitors store the

electric energy

Electrical energy is energy related to forces on electrically charged particles and the movement of electrically charged particles (often electrons in wires, but not always). This energy is supplied by the combination of electric current and electr ...

statically by

charge

Charge or charged may refer to:

Arts, entertainment, and media Films

* '' Charge, Zero Emissions/Maximum Speed'', a 2011 documentary

Music

* ''Charge'' (David Ford album)

* ''Charge'' (Machel Montano album)

* ''Charge!!'', an album by The Aqu ...

separation in an

electric field

An electric field (sometimes E-field) is the physical field that surrounds electrically charged particles and exerts force on all other charged particles in the field, either attracting or repelling them. It also refers to the physical field fo ...

in the dielectric oxide layer between two

electrode

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit (e.g. a semiconductor, an electrolyte, a vacuum or air). Electrodes are essential parts of batteries that can consist of a variety of materials de ...

s. The non-solid or solid

electrolyte

An electrolyte is a medium containing ions that is electrically conducting through the movement of those ions, but not conducting electrons. This includes most soluble salts, acids, and bases dissolved in a polar solvent, such as water. Upon dis ...

in principle is the cathode, which thus forms the second electrode of the capacitor. This and the storage principle distinguish them from electrochemical capacitors or

supercapacitors, in which the electrolyte generally is the ionic conductive connection between two electrodes and the storage occurs with statically

double-layer capacitance Double-layer capacitance is the important characteristic of the electrical double layer which appears, for example, at the interface between a conductive electrode and an adjacent liquid electrolyte. At this boundary two layers of charge with oppo ...

and electrochemical

pseudocapacitance

Pseudocapacitance is the Electrochemistry, electrochemical storage of electricity in an Supercapacitor, electrochemical capacitor (Pseudocapacitor). This faradaic charge transfer originates by a very fast sequence of reversible Faradaic current, fa ...

.

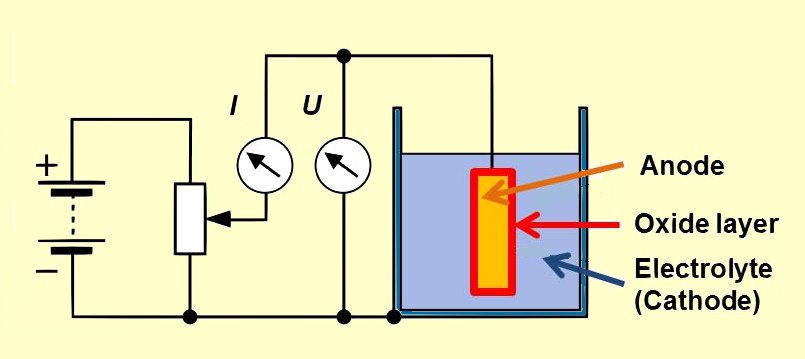

Basic materials and construction

Electrolytic capacitors use a chemical feature of some special metals, previously called "valve metals", which on contact with a particular electrolyte form a very thin insulating oxide layer on their surface by

anodic

An anode is an electrode of a polarized electrical device through which conventional current enters the device. This contrasts with a cathode, an electrode of the device through which conventional current leaves the device. A common mnemonic is ...

oxidation

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or a d ...

which can function as a dielectric. There are three different anode metals in use for electrolytic capacitors:

#

Aluminum electrolytic capacitor

Aluminum electrolytic capacitors are polarized electrolytic capacitors whose anode electrode (+) is made of a pure aluminum foil with an etched surface. The aluminum forms a very thin insulating layer of aluminum oxide by anodization that acts ...

s use a high-purity etched

aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. I ...

foil with

aluminium oxide as dielectric

#

Tantalum electrolytic capacitors use a sintered pellet (“slug”) of high-purity

tantalum

Tantalum is a chemical element with the symbol Ta and atomic number 73. Previously known as ''tantalium'', it is named after Tantalus, a villain in Greek mythology. Tantalum is a very hard, ductile, lustrous, blue-gray transition metal that is ...

powder with

tantalum pentoxide

Tantalum pentoxide, also known as tantalum(V) oxide, is the inorganic compound with the formula . It is a white solid that is insoluble in all solvents but is attacked by strong bases and hydrofluoric acid. is an inert material with a high refract ...

as dielectric

#

Niobium electrolytic capacitors use a sintered "slug" of high-purity

niobium

Niobium is a chemical element with chemical symbol Nb (formerly columbium, Cb) and atomic number 41. It is a light grey, crystalline, and ductile transition metal. Pure niobium has a Mohs hardness rating similar to pure titanium, and it has sim ...

or

niobium oxide Niobium oxide, sometimes called columbium oxide, may refer to:

* Niobium monoxide (niobium(II) oxide), NbO

* Niobium dioxide (niobium(IV) oxide), NbO2

* Niobium pentoxide (niobium(V) oxide), Nb2O5

In addition to the above, other distinct oxides ...

powder with

niobium pentoxide

Niobium pentoxide is the inorganic compound with the formula Nb2 O5. A colorless, insoluble, and fairly unreactive solid, it is the most widespread precursor for other compounds and materials containing niobium. It is predominantly used in alloyi ...

as dielectric.

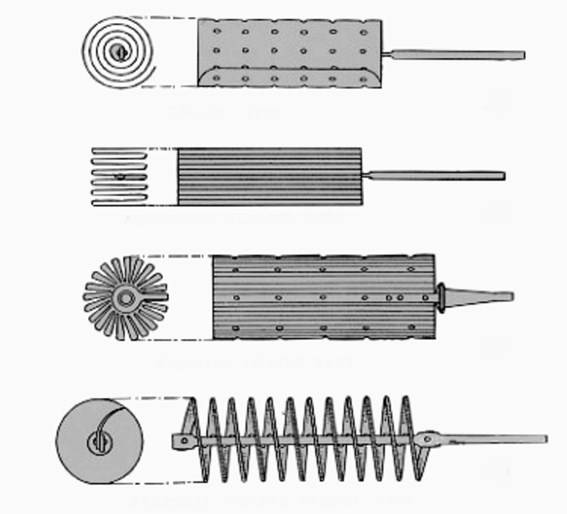

To increase their capacitance per unit volume, all anode materials are either etched or sintered and have a rough surface structure with a much higher surface area compared to a smooth surface of the same area or the same volume. By applying a positive voltage to the above-mentioned anode material in an electrolytic bath an oxide barrier layer with a thickness corresponding to the applied voltage will be formed (formation). This oxide layer acts as dielectric in an electrolytic capacitor. The properties of this oxide layers are given in the following table:

After forming a dielectric oxide on the rough anode structure, a counter electrode has to match the rough insulating oxide surface. This is accomplished by the electrolyte, which acts as the cathode electrode of an electrolytic capacitor. There are many different electrolytes in use. Generally they are distinguished into two species, “non-solid” and “solid” electrolytes. As a liquid medium which has

ion

An ion () is an atom or molecule with a net electrical charge.

The charge of an electron is considered to be negative by convention and this charge is equal and opposite to the charge of a proton, which is considered to be positive by conve ...

conductivity

Conductivity may refer to:

*Electrical conductivity, a measure of a material's ability to conduct an electric current

**Conductivity (electrolytic), the electrical conductivity of an electrolyte in solution

** Ionic conductivity (solid state), ele ...

caused by moving ions, non-solid electrolytes can easily fit the rough structures. Solid electrolytes which have electron conductivity can fit the rough structures with the help of special chemical processes like

pyrolysis

The pyrolysis (or devolatilization) process is the thermal decomposition of materials at elevated temperatures, often in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements ''py ...

for

manganese dioxide

Manganese dioxide is the inorganic compound with the formula . This blackish or brown solid occurs naturally as the mineral pyrolusite, which is the main ore of manganese and a component of manganese nodules. The principal use for is for dry-cell ...

or

polymerization

In polymer chemistry, polymerization (American English), or polymerisation (British English), is a process of reacting monomer, monomer molecules together in a chemical reaction to form polymer chains or three-dimensional networks. There are ...

for conducting

polymer

A polymer (; Greek '' poly-'', "many" + ''-mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic a ...

s.

Comparing the permittivities of the different oxide materials it is seen that tantalum pentoxide has a permittivity approximately three times higher than aluminum oxide. Tantalum electrolytic capacitors of a given CV value theoretically are therefore smaller than aluminium electrolytic capacitors. In practice different safety margins to reach reliable components makes a comparison difficult.

The anodically generated insulating oxide layer is destroyed if the polarity of the applied voltage changes.

Capacitance and volumetric efficiency

Electrolytic capacitors are based on the principle of a "plate capacitor" whose capacitance increases with larger electrode area A, higher dielectric

permittivity

In electromagnetism, the absolute permittivity, often simply called permittivity and denoted by the Greek letter ''ε'' ( epsilon), is a measure of the electric polarizability of a dielectric. A material with high permittivity polarizes more in ...

ε, and thinness of dielectric (d).

:

The dielectric thickness of electrolytic capacitors is very small, in the range of

nanometers

330px, Different lengths as in respect to the molecular scale.

The nanometre (international spelling as used by the International Bureau of Weights and Measures; SI symbol: nm) or nanometer (American and British English spelling differences#-re ...

per volt. On the other hand, the voltage strengths of these oxide layers are quite high. With this very thin dielectric oxide layer combined with a sufficiently high dielectric strength the electrolytic capacitors can achieve a high volumetric capacitance. This is one reason for the high capacitance values of electrolytic capacitors compared to conventional capacitors.

All etched or sintered anodes have a much higher surface area compared to a smooth surface of the same area or the same volume. That increases the capacitance value, depending on the rated voltage, by a factor of up to 200 for non-solid aluminium electrolytic capacitors as well as for solid tantalum electrolytic capacitors.

[A. Albertsen, Jianghai Europe, Keep your distance – Voltage Proof of Electrolytic Capacitors]

PDF

[I.Horacek, T.Zednicek, S.Zednicek, T.Karnik, J.Petrzilek, P.Jacisko, P.Gregorova, AVX, High CV Tantalum Capacitors - Challenges and Limitation]

The large surface compared to a smooth one is the second reason for the relatively high capacitance values of electrolytic capacitors compared with other capacitor families.

Because the forming voltage defines the oxide layer thickness, the desired voltage rating can be produced very simply. Electrolytic capacitors have high

volumetric efficiency Volumetric efficiency (VE) in internal combustion engine engineering is defined as the ratio of the mass density of the air-fuel mixture drawn into the cylinder at atmospheric pressure (during the intake stroke) to the mass density of the same volu ...

, the so-called "CV product", defined as the product of capacitance and voltage divided by volume.

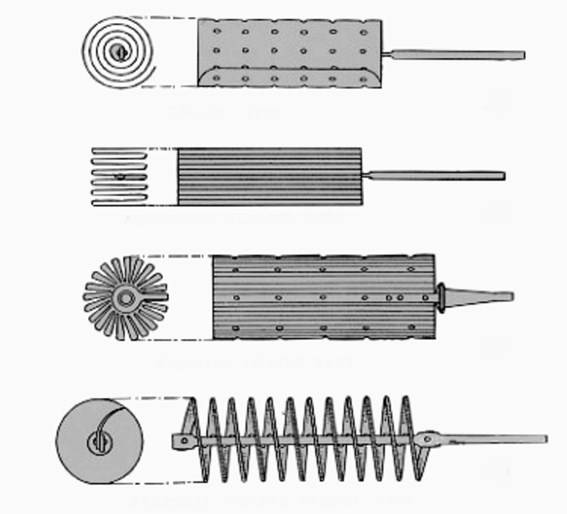

Basic construction of non-solid aluminum electrolytic capacitors

File:Al-e-cap-winding-multi-tabs.jpg, Opened winding of an electrolytic capacitor with multiple connected foils

File: Elko-Prinzipschnittbild-english.png, Closeup cross-section of an aluminium electrolytic capacitor design, showing capacitor anode foil with oxide layer, paper spacer soaked with electrolyte, and cathode foil

File:Al-e-cap-construction.jpg, Construction of a typical single-ended aluminium electrolytic capacitor with non-solid electrolyte

Basic construction of solid tantalum electrolytic capacitors

File:Tantalum sintered pellet.jpg, The capacitor cell of a tantalum electrolytic capacitor consists of sintered tantalum powder

File:Tantalum-Sintered-MnO2-slug.jpg, Schematic representation of the structure of a sintered tantalum electrolytic capacitor with solid electrolyte and the cathode contacting layers

File:Tantalum-SMD-Chip-Molded.jpg, Construction of a typical SMD tantalum electrolytic chip capacitor with solid electrolyte

Types and features of electrolytic capacitors

Comparison of electrolytic capacitor types

Combinations of anode materials for electrolytic capacitors and the electrolytes used have given rise to wide varieties of capacitor types with different properties. An outline of the main characteristics of the different types is shown in the table below.

The non-solid or so-called "wet" aluminum electrolytic capacitors were and are the cheapest among all other conventional capacitors. They not only provide the cheapest solutions for high capacitance or voltage values for decoupling and buffering purposes but are also insensitive to low ohmic charging and discharging as well as to low-energy transients. Non-solid electrolytic capacitors can be found in nearly all areas of electronic devices, with the exception of military applications.

Tantalum electrolytic capacitors with solid electrolyte as surface-mountable chip capacitors are mainly used in electronic devices in which little space is available or a low profile is required. They operate reliably over a wide temperature range without large parameter deviations. In military and space applications only tantalum electrolytic capacitors have the necessary approvals.

Niobium electrolytic capacitors are in direct competition with industrial tantalum electrolytic capacitors because niobium is more readily available. Their properties are comparable.

The electrical properties of aluminum, tantalum and niobium electrolytic capacitors have been greatly improved by the polymer electrolyte.

Comparison of electrical parameters

In order to compare the different characteristics of the different electrolytic capacitor types, capacitors with the same dimensions and of similar capacitance and voltage are compared in the following table. In such a comparison the values for ESR and ripple current load are the most important parameters for the use of electrolytic capacitors in modern electronic equipment. The lower the ESR, the higher the ripple current per volume and better functionality of the capacitor in the circuit. However, better electrical parameters come with higher prices.

1) Manufacturer, series name, capacitance/voltage

2) calculated for a capacitor 100 µF/10 V,

3) from a 1976 data sheet

Styles of aluminum and tantalum electrolytic capacitors

Aluminum electrolytic capacitors form the bulk of the electrolytic capacitors used in electronics because of the large diversity of sizes and the inexpensive production. Tantalum electrolytic capacitors, usually used in the SMD version, have a higher specific capacitance than the aluminum electrolytic capacitors and are used in devices with limited space or flat design such as laptops. They are also used in military technology, mostly in axial style, hermetically sealed. Niobium electrolytic chip capacitors are a new development in the market and are intended as a replacement for tantalum electrolytic chip capacitors.

File:V-Chip-Elkos.png, Aluminum electrolytic SMD "V" (vertical) chip capacitors

File:Axial electrolytic capacitors.jpg, Axial style aluminum electrolytic capacitors

File:Single-ended-e-caps-IMG 5117.JPG, Radial or single-ended aluminum electrolytic capacitors

File:Snap-In Electrolytic Capacitor.jpg, Aluminum electrolytic capacitor with "snap-in" terminals

File:Screw-terminal-e-caps-IMG 5126.JPG, Aluminum electrolytic capacitors with screw terminals

File:CMS tantalum capacitor.JPG, Typical tantalum SMD capacitor

File:Tantalum capacitors.jpg, Dipped lacquered tantalum “pearl” capacitors

File:Tantal-Elko-Axial-P1040292c.jpg, Axial style tantalum electrolytic capacitors

History

Origin

The phenomenon that in an electrochemical process, aluminum and such metals as

tantalum

Tantalum is a chemical element with the symbol Ta and atomic number 73. Previously known as ''tantalium'', it is named after Tantalus, a villain in Greek mythology. Tantalum is a very hard, ductile, lustrous, blue-gray transition metal that is ...

,

niobium

Niobium is a chemical element with chemical symbol Nb (formerly columbium, Cb) and atomic number 41. It is a light grey, crystalline, and ductile transition metal. Pure niobium has a Mohs hardness rating similar to pure titanium, and it has sim ...

,

manganese

Manganese is a chemical element with the symbol Mn and atomic number 25. It is a hard, brittle, silvery metal, often found in minerals in combination with iron. Manganese is a transition metal with a multifaceted array of industrial alloy use ...

,

titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in ...

,

zinc

Zinc is a chemical element with the symbol Zn and atomic number 30. Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodi ...

,

cadmium

Cadmium is a chemical element with the symbol Cd and atomic number 48. This soft, silvery-white metal is chemically similar to the two other stable metals in group 12, zinc and mercury. Like zinc, it demonstrates oxidation state +2 in most of ...

, etc., can form an oxide layer which blocks an electric current from flowing in one direction but which allows current to flow in the opposite direction, was first observed in 1857 by the German physicist and chemist

Johann Heinrich Buff

Johann, typically a male given name, is the German language, German form of ''Iohannes'', which is the Latin language, Latin form of the Greek language, Greek name ''Iōánnēs'' (), itself derived from Hebrew language, Hebrew name ''Johanan (name ...

(1805–1878). It was first put to use in 1875 by the French researcher and founder

Eugène Ducretet

Eugene is a common male given name that comes from the Greek language, Greek εὐγενής (''eugenēs''), "noble", literally "well-born", from εὖ (''eu''), "well" and γένος (''genos''), "race, stock, kin".Karol Pollak

Karol Franciszek Pollak (November 15, 1859 – December 17, 1928) was a Polish electrotechnician, inventor and businessman.

Early life

He was born in Sanok, Kingdom of Galicia and Lodomeria, part of the Austrian Empire . His father was Karol ...

), a producer of accumulators, found out that the oxide layer on an aluminum anode remained stable in a neutral or alkaline electrolyte, even when the power was switched off. In 1896 he filed a patent for an "Electric liquid capacitor with aluminum electrodes" (de: ''Elektrischer Flüssigkeitskondensator mit Aluminiumelektroden'') based on his idea of using the oxide layer in a polarized capacitor in combination with a neutral or slightly alkaline electrolyte.

"Wet" aluminum capacitor

The first industrially realized electrolytic capacitors consisted of a metallic box used as the cathode. It was filled with a

borax

Borax is a salt ( ionic compound), a hydrated borate of sodium, with chemical formula often written . It is a colorless crystalline solid, that dissolves in water to make a basic solution. It is commonly available in powder or granular for ...

electrolyte dissolved in water, in which a folded aluminum anode plate was inserted. Applying a DC voltage from outside, an oxide layer was formed on the surface of the anode. The advantage of these capacitors was that they were significantly smaller and cheaper than all other capacitors at this time relative to the realized capacitance value. This construction with different styles of anode construction but with a case as cathode and container for the electrolyte was used up to the 1930s and was called a "wet" electrolytic capacitor, in the sense of its having a high water content.

The first more common application of wet aluminum electrolytic capacitors was in large telephone exchanges, to reduce

relay hash (noise) on the 48 volt DC power supply. The development of AC-operated domestic radio receivers in the late 1920s created a demand for large-capacitance (for the time) and high-voltage capacitors for the

valve amplifier

A valve amplifier or tube amplifier is a type of electronic amplifier that uses vacuum tubes to increase the amplitude or power of a signal. Low to medium power valve amplifiers for frequencies below the microwaves were largely replaced by sol ...

technique, typically at least 4 microfarads and rated at around 500 volts DC. Waxed paper and oiled silk

film capacitor

Film capacitors, plastic film capacitors, film dielectric capacitors, or polymer film capacitors, generically called film caps as well as power film capacitors, are electrical capacitors with an insulating plastic film as the dielectric, sometime ...

s were available, but devices with that order of capacitance and voltage rating were bulky and prohibitively expensive.

"Dry" aluminum capacitor

The

ancestor

An ancestor, also known as a forefather, fore-elder or a forebear, is a parent or (recursively) the parent of an antecedent (i.e., a grandparent, great-grandparent, great-great-grandparent and so forth). ''Ancestor'' is "any person from whom ...

of the modern electrolytic capacitor was patented by

Samuel Ruben

Samuel Ruben (14 July 1900 – 16 July 1988) was an American inventor who made lasting contributions to electrochemistry and solid-state technology, including the founding of Duracell. He is listed as an inventor in ove200 patents. Early life

Born ...

in 1925, who teamed with

Philip Mallory

Philip Rogers Mallory (November 11, 1885 - November 16, 1975) was an American businessman and the founder of the company that is now known as Duracell International. Rather than making a career in his family's shipping business, he founded his own ...

, the founder of the battery company that is now known as

Duracell International. Ruben's idea adopted the stacked construction of a

silver mica capacitor

Silver mica capacitors are high precision, stable and reliable capacitors. They are available in small values, and are mostly used at high frequencies and in cases where low losses (high Q) and low capacitor change over time is desired.

History

M ...

. He introduced a separated second foil to contact the electrolyte adjacent to the anode foil instead of using the electrolyte-filled container as the capacitor's cathode. The stacked second foil got its own terminal additional to the anode terminal and the container no longer had an electrical function. This type of electrolytic capacitor combined with a liquid or gel-like electrolyte of a non-aqueous nature, which is therefore dry in the sense of having a very low water content, became known as the "dry" type of electrolytic capacitor.

[P. McK. Deeley, Electrolytic Capacitors, The Cornell-Dubilier Electric Corp. South Plainfield New Jersey, 1938]

With Ruben's invention, together with the invention of wound foils separated with a paper spacer 1927 by A. Eckel of Hydra-Werke (Germany), the actual development of electrolytic capacitors began.

William Dubilier

William Dubilier (July 25, 1888 – July 25, 1969) was an American inventor in the field of radio and electronics. He demonstrated radio communication at Seattle's Alaska–Yukon–Pacific Exposition on June 21, 1909; ten years before the first c ...

, whose first patent for electrolytic capacitors was filed in 1928, industrialized the new ideas for electrolytic capacitors and started the first large commercial production in 1931 in the Cornell-Dubilier (CD) factory in Plainfield, New Jersey.

At the same time in Berlin, Germany, the "Hydra-Werke", an

AEG

Allgemeine Elektricitäts-Gesellschaft AG (AEG; ) was a German producer of electrical equipment founded in Berlin as the ''Deutsche Edison-Gesellschaft für angewandte Elektricität'' in 1883 by Emil Rathenau. During the Second World War, AEG ...

company, started the production of electrolytic capacitors in large quantities. Another manufacturer,

Ralph D. Mershon

Ralph Davenport Mershon (1868–1952) was an electrical engineer and inventor. His company Mershon Condensers was a successful manufacturer of electrolytic capacitors for the expanding radio market of the 1920s. He is known for the Mershon Aud ...

, had success in servicing the radio-market demand for electrolytic capacitors.

In his 1896 patent Pollak already recognized that the capacitance of the capacitor increases when roughening the surface of the anode foil. Today (2014), electrochemically etched low voltage foils can achieve an up to 200-fold increase in surface area compared to a smooth surface.

Advances in the etching process are the reason for the dimension reductions in aluminum electrolytic capacitors over recent decades.

For aluminum electrolytic capacitors the decades from 1970 to 1990 were marked by the development of various new professional series specifically suited to certain industrial applications, for example with very low leakage currents or with long life characteristics, or for higher temperatures up to 125 °C.

Tantalum capacitors

One of the first tantalum electrolytic capacitors were developed in 1930 by Tansitor Electronic Inc. USA, for military purposes. The basic construction of a wound cell was adopted and a tantalum anode foil was used together with a tantalum cathode foil, separated with a paper spacer impregnated with a liquid electrolyte, mostly sulfuric acid, and encapsulated in a silver case.

The relevant development of solid electrolyte tantalum capacitors began some years after

William Shockley

William Bradford Shockley Jr. (February 13, 1910 – August 12, 1989) was an American physicist and inventor. He was the manager of a research group at Bell Labs that included John Bardeen and Walter Brattain. The three scientists were jointly ...

,

John Bardeen

John Bardeen (; May 23, 1908 – January 30, 1991) was an American physicist and engineer. He is the only person to be awarded the Nobel Prize in Physics twice: first in 1956 with William Shockley and Walter Brattain for the invention of the tran ...

and

Walter Houser Brattain

Walter Houser Brattain (; February 10, 1902 – October 13, 1987) was an American physicist at Bell Labs who, along with fellow scientists John Bardeen and William Shockley, invented the point-contact transistor in December 1947. They shared t ...

invented the

transistor

upright=1.4, gate (G), body (B), source (S) and drain (D) terminals. The gate is separated from the body by an insulating layer (pink).

A transistor is a semiconductor device used to Electronic amplifier, amplify or electronic switch, switch e ...

in 1947. It was invented by

Bell Laboratories

Nokia Bell Labs, originally named Bell Telephone Laboratories (1925–1984),

then AT&T Bell Laboratories (1984–1996)

and Bell Labs Innovations (1996–2007),

is an American industrial research and scientific development company owned by mult ...

in the early 1950s as a miniaturized, more reliable low-voltage support capacitor to complement their newly invented transistor. The solution found by R. L. Taylor and H. E. Haring at Bell Labs in early 1950 was based on experience with ceramics. They ground tantalum to a powder, which they pressed into a cylindrical form and then

sintered at a high temperature between 1500 and 2000 °C under vacuum conditions, to produce a pellet ("slug").

These first sintered tantalum capacitors used a non-solid electrolyte, which does not fit the concept of solid electronics. In 1952 a targeted search at Bell Labs by D. A. McLean and F. S. Power for a solid electrolyte led to the invention of manganese dioxide as a solid electrolyte for a sintered tantalum capacitor.

Although fundamental inventions came from Bell Labs, the inventions for manufacturing commercially viable tantalum electrolytic capacitors came from researchers at the

Sprague Electric Company.

Preston Robinson, Sprague's Director of Research, is considered to be the actual inventor of tantalum capacitors in 1954. His invention was supported by R. J. Millard, who introduced the "reform" step in 1955, a significant improvement in which the dielectric of the capacitor was repaired after each dip-and-convert cycle of MnO

2 deposition, which dramatically reduced the leakage current of the finished capacitors.

Although solid tantalum capacitors offered capacitors with lower ESR and leakage current values than the aluminum electrolytic capacitors, a 1980 price shock for tantalum dramatically reduced the applications of tantalum electrolytic capacitors, especially in the entertainment industry. The industry switched back to using aluminum electrolytic capacitors.

Solid electrolytes

The first solid electrolyte of manganese dioxide developed 1952 for tantalum capacitors had a conductivity 10 times better than all other types of non-solid electrolytes. It also influenced the development of aluminum electrolytic capacitors. In 1964 the first aluminum electrolytic capacitors with solid electrolyte

SAL electrolytic capacitor came on the market, developed by

Philips

Koninklijke Philips N.V. (), commonly shortened to Philips, is a Dutch multinational conglomerate corporation that was founded in Eindhoven in 1891. Since 1997, it has been mostly headquartered in Amsterdam, though the Benelux headquarters i ...

.

With the beginning of digitalization, Intel launched its first microcomputer, the MCS 4, in 1971. In 1972 Hewlett Packard launched one of the first pocket calculators, the HP 35. The requirements for capacitors increased in terms of lowering the

equivalent series resistance

Practical capacitors and inductors as used in electric circuits are not ideal components with only capacitance or inductance. However, they can be treated, to a very good degree of approximation, as being ideal capacitors and inductors in series ...

(ESR) for bypass and decoupling capacitors.

It was not until 1983 when a new step toward ESR reduction was taken by

Sanyo

, stylized as SANYO, is a Japanese electronics company and formerly a member of the Fortune Global 500, ''Fortune'' Global 500 whose headquarters was located in Moriguchi, Osaka, Moriguchi, Osaka prefecture, Japan. Sanyo had over 230 subsidiari ...

with its "

OS-CON

A polymer capacitor, or more accurately a polymer electrolytic capacitor, is an electrolytic capacitor (e-cap) with a solid conductive polymer electrolyte. There are four different types:

* Polymer tantalum electrolytic capacitor (Polymer Ta-e- ...

" aluminum electrolytic capacitors. These capacitors used a solid organic conductor, the charge transfer salt TTF-TCNQ (

tetracyanoquinodimethane

Tetracyanoquinodimethane (TCNQ) is the organic compound with the formula . This cyanocarbon, a relative of para-quinone, is an electron acceptor that is used to prepare charge transfer salts, which are of interest in molecular electronics.

P ...

), which provided an improvement in conductivity by a factor of 10 compared with the manganese dioxide electrolyte.

The next step in ESR reduction was the development of

conducting polymer

Conductive polymers or, more precisely, intrinsically conducting polymers (ICPs) are organic polymers that conduct electricity. Such compounds may have metallic conductivity or can be semiconductors. The biggest advantage of conductive polymers ...

s by

Alan J. Heeger,

Alan MacDiarmid

Alan Graham MacDiarmid, ONZ FRS (14 April 1927 – 7 February 2007) was a New Zealand-born American chemist, and one of three recipients of the Nobel Prize for Chemistry in 2000.

Early life and education

MacDiarmid was born in Masterton, New ...

and

Hideki Shirakawa

is a Japanese chemist, engineer, and Professor Emeritus at the University of Tsukuba and Zhejiang University. He is best known for his discovery of conductive polymers. He was co-recipient of the 2000 Nobel Prize in Chemistry jointly with Alan Ma ...

in 1975. The conductivity of conductive polymers such as

polypyrrole

Polypyrrole (PPy) is an organic polymer obtained by oxidative polymerization of pyrrole. It is a solid with the formula H(C4H2NH)nH. It is an intrinsically conducting polymer, used in electronics, optical, biological and medical fields.

History ...

(PPy) or

PEDOT

Poly(3,4-ethylenedioxythiophene) (PEDOT or PEDT; ''IUPAC'' name poly(2,3-dihydrothieno ,4-''b''1,4]dioxane-5,7-diyl)) is a conducting polymer based on 3,4-Ethylenedioxythiophene, 3,4-ethylenedioxythiophene or EDOT. It was first reported by Baye ...

is better than that of TCNQ by a factor of 100 to 500, and close to the conductivity of metals.

In 1991 Panasonic released its "SP-Cap", series of

Polymer capacitor, polymer aluminum electrolytic capacitors. These aluminum electrolytic capacitors with polymer electrolytes reached very low ESR values directly comparable to

ceramic multilayer capacitors (MLCCs). They were still less expensive than tantalum capacitors and with their flat design for

laptop

A laptop, laptop computer, or notebook computer is a small, portable personal computer (PC) with a screen and alphanumeric keyboard. Laptops typically have a clam shell form factor with the screen mounted on the inside of the upper li ...

s and

cell phones competed with tantalum chip capacitors as well.

Tantalum electrolytic capacitors with PPy polymer electrolyte cathode followed three years later. In 1993 NEC introduced its SMD polymer tantalum electrolytic capacitors, called "NeoCap". In 1997 Sanyo followed with the "POSCAP" polymer tantalum chips.

A new conductive polymer for tantalum polymer capacitors was presented by Kemet at the "1999 Carts" conference. This capacitor used the newly developed organic conductive polymer PEDT Poly(3,4-ethylenedioxythiophene), also known as PEDOT (trade name Baytron®)

Niobium capacitors

Another price explosion for tantalum in 2000/2001 forced the development of niobium electrolytic capacitors with manganese dioxide electrolyte, which have been available since 2002. Niobium is a sister metal to tantalum and serves as valve metal generating an oxide layer during anodic oxidation. Niobium as raw material is much more abundant in nature than tantalum and is less expensive. It was a question of the availability of the base metal in the late 1960s which led to development and implementation of niobium electrolytic capacitors in the former Soviet Union instead of tantalum capacitors as in the West. The materials and processes used to produce niobium-dielectric capacitors are essentially the same as for existing tantalum-dielectric capacitors. The characteristics of niobium electrolytic capacitors and tantalum electrolytic capacitors are roughly comparable.

Water-based electrolytes

With the goal of reducing ESR for inexpensive non-solid electrolytic capacitors from the mid-1980s in Japan, new water-based electrolytes for aluminum electrolytic capacitors were developed. Water is inexpensive, an effective solvent for electrolytes, and significantly improves the conductivity of the electrolyte. The Japanese manufacturer

Rubycon was a leader in the development of new water-based electrolyte systems with enhanced conductivity in the late 1990s.

[Shigeru Uzawa, Akihiko Komat-u, Tetsushi Ogawara, Rubycon Corporation, Ultra Low Impedance Aluminum Electrolytic Capacitor with Water based Electrolyte or ] The new series of non-solid electrolytic capacitors with water-based electrolyte was described in the data sheets as having "low ESR", "low impedance", "ultra-low impedance" or "high ripple current".

From 1999 through at least 2010, a stolen recipe for such a water-based electrolyte, in which important stabilizers

[J. L. Stevens, T. R. Marshall, A. C. Geiculescu m, C. R. Feger, T. F. Strange, Carts USA 2006, The Effects of Electrolyte Composition on the Deformation Characteristics of Wet Aluminum ICD Capacitors]

[Alfonso Berduque, Zongli Dou, Rong Xu, KEMET, Electrochemical Studies for Aluminium Electrolytic Capacitor Applications: Corrosion Analysis of Aluminium in Ethylene Glycol-Based Electrolyte]

PDF

/ref> were absent,cottage

A cottage, during Feudalism in England, England's feudal period, was the holding by a cottager (known as a Cotter (farmer), cotter or ''bordar'') of a small house with enough garden to feed a family and in return for the cottage, the cottager ...

repair industry.

Electrical characteristics

Series-equivalent circuit

The electrical characteristics of capacitors are harmonized by the international generic specification IEC 60384-1. In this standard, the electrical characteristics of capacitors are described by an idealized series-equivalent circuit with electrical components which model all ohmic losses, capacitive and inductive parameters of an electrolytic capacitor:

* ''C'', the capacitance of the capacitor

* ''R''ESR, the

The electrical characteristics of capacitors are harmonized by the international generic specification IEC 60384-1. In this standard, the electrical characteristics of capacitors are described by an idealized series-equivalent circuit with electrical components which model all ohmic losses, capacitive and inductive parameters of an electrolytic capacitor:

* ''C'', the capacitance of the capacitor

* ''R''ESR, the equivalent series resistance

Practical capacitors and inductors as used in electric circuits are not ideal components with only capacitance or inductance. However, they can be treated, to a very good degree of approximation, as being ideal capacitors and inductors in series ...

which summarizes all ohmic losses of the capacitor, usually abbreviated as "ESR"

* ''L''ESL, the equivalent series inductance

Equivalent series inductance (ESL) is an effective inductance that is used to describe the inductive part of the impedance of certain electrical components.

Overview

The theoretical treatment of devices such as capacitors and resistors tends to ...

which is the effective self-inductance of the capacitor, usually abbreviated as "ESL".

* ''R''leak, the resistance representing the leakage current

In electronics, leakage is the gradual transfer of electrical energy across a boundary normally viewed as insulating, such as the spontaneous discharge of a charged capacitor, magnetic coupling of a transformer with other components, or flow of cu ...

of the capacitor

Capacitance, standard values and tolerances

The electrical characteristics of electrolytic capacitors depend on the structure of the anode and the electrolyte used. This influences the capacitance value of electrolytic capacitors, which depends on measuring frequency and temperature. Electrolytic capacitors with non-solid electrolytes show a broader aberration over frequency and temperature ranges than do capacitors with solid electrolytes.

The basic unit of an electrolytic capacitor's capacitance is the microfarad

The farad (symbol: F) is the unit of electrical capacitance, the ability of a body to store an electrical charge, in the International System of Units (SI). It is named after the English physicist Michael Faraday (1791–1867). In SI base unit ...

(μF). The capacitance value specified in the data sheets of the manufacturers is called the rated capacitance CR or nominal capacitance CN and is the value for which the capacitor has been designed.

The standardized measuring condition for electrolytic capacitors is an AC measuring method with 0.5 V at a frequency of 100/120 Hz at a temperature of 20 °C. For tantalum capacitors a DC bias voltage of 1.1 to 1.5 V for types with a rated voltage ≤2.5 V, or 2.1 to 2.5 V for types with a rated voltage of >2.5 V, may be applied during the measurement to avoid reverse voltage.

The capacitance value measured at the frequency of 1 kHz is about 10% less than the 100/120 Hz value. Therefore, the capacitance values of electrolytic capacitors are not directly comparable and differ from those of film capacitor

Film capacitors, plastic film capacitors, film dielectric capacitors, or polymer film capacitors, generically called film caps as well as power film capacitors, are electrical capacitors with an insulating plastic film as the dielectric, sometime ...

s or ceramic capacitor

A ceramic capacitor is a fixed-value capacitor where the ceramic material acts as the dielectric. It is constructed of two or more alternating layers of ceramic and a metal layer acting as the electrodes. The composition of the ceramic material de ...

s, whose capacitance is measured at 1 kHz or higher.

Measured with an AC measuring method at 100/120 Hz the capacitance value is the closest value to the electrical charge stored in the e-caps. The stored charge is measured with a special discharge method and is called the DC capacitance. The DC capacitance is about 10% higher than the 100/120 Hz AC capacitance. The DC capacitance is of interest for discharge applications like photoflash

A flash is a device used in photography that produces a brief burst of light (typically lasting 1/1000 to 1/200 of a second) at a color temperature of about 5500 K to help illuminate a scene. A major purpose of a flash is to illuminate a ...

.

The percentage of allowed deviation of the measured capacitance from the rated value is called the capacitance tolerance. Electrolytic capacitors are available in different tolerance series, whose values are specified in the E series E series may refer to:

* BMC E-series engine, a series of automobile engines

* Electronic E series of preferred numbers, a series of preferred values for electronic components such as resistors, capacitors, inductors, zener diodes

* Entwicklung seri ...

specified in IEC 60063. For abbreviated marking in tight spaces, a letter code for each tolerance is specified in IEC 60062.

* rated capacitance, series E3, tolerance ±20%, letter code "M"

* rated capacitance, series E6, tolerance ±20%, letter code "M"

* rated capacitance, series E12, tolerance ±10%, letter code "K"

The required capacitance tolerance is determined by the particular application. Electrolytic capacitors, which are often used for filtering and bypassing, do not have the need for narrow tolerances because they are mostly not used for accurate frequency applications like in oscillator

Oscillation is the repetitive or periodic variation, typically in time, of some measure about a central value (often a point of equilibrium) or between two or more different states. Familiar examples of oscillation include a swinging pendulum ...

s.

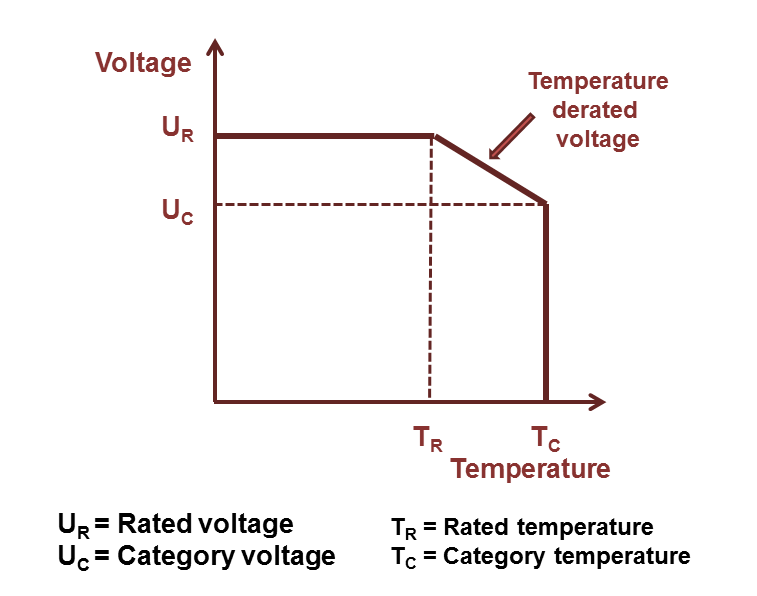

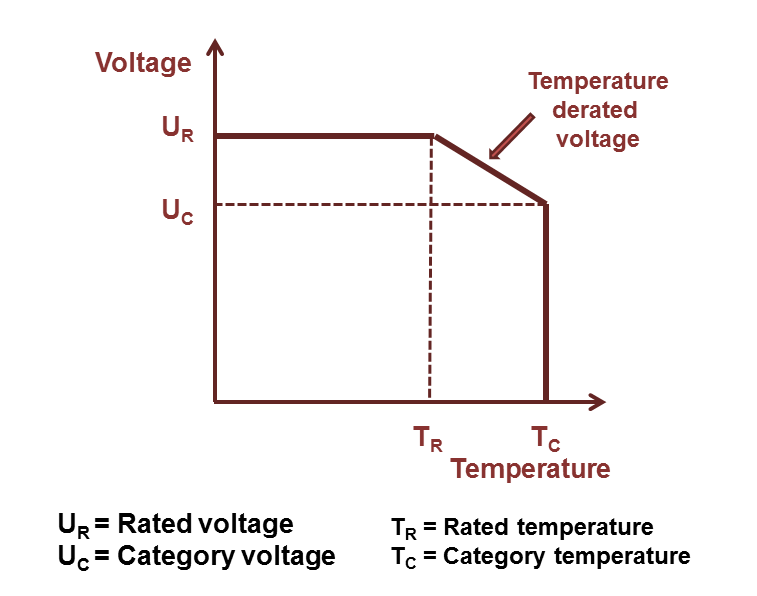

Rated and category voltage

Referring to the IEC/EN 60384-1 standard, the allowed operating voltage for electrolytic capacitors is called the "rated voltage UR" or "nominal voltage UN". The rated voltage UR is the maximum DC voltage or peak pulse voltage that may be applied continuously at any temperature within the rated temperature range TR.

The voltage proof of electrolytic capacitors decreases with increasing temperature. For some applications it is important to use a higher temperature range. Lowering the voltage applied at a higher temperature maintains safety margins. For some capacitor types therefore the IEC standard specifies a "temperature derated voltage" for a higher temperature, the "category voltage UC". The category voltage is the maximum DC voltage or peak pulse voltage that may be applied continuously to a capacitor at any temperature within the category temperature range TC. The relation between both voltages and temperatures is given in the picture at right.

Applying a higher voltage than specified may destroy electrolytic capacitors.

Applying a lower voltage may have a positive influence on electrolytic capacitors. For aluminum electrolytic capacitors a lower applied voltage can in some cases extend the lifetime.

Referring to the IEC/EN 60384-1 standard, the allowed operating voltage for electrolytic capacitors is called the "rated voltage UR" or "nominal voltage UN". The rated voltage UR is the maximum DC voltage or peak pulse voltage that may be applied continuously at any temperature within the rated temperature range TR.

The voltage proof of electrolytic capacitors decreases with increasing temperature. For some applications it is important to use a higher temperature range. Lowering the voltage applied at a higher temperature maintains safety margins. For some capacitor types therefore the IEC standard specifies a "temperature derated voltage" for a higher temperature, the "category voltage UC". The category voltage is the maximum DC voltage or peak pulse voltage that may be applied continuously to a capacitor at any temperature within the category temperature range TC. The relation between both voltages and temperatures is given in the picture at right.

Applying a higher voltage than specified may destroy electrolytic capacitors.

Applying a lower voltage may have a positive influence on electrolytic capacitors. For aluminum electrolytic capacitors a lower applied voltage can in some cases extend the lifetime.[Ch. Reynolds, AVX, Technical Information, Reliability Management of Tantalum Capacitors]

PDF

I

Surge voltage

The surge voltage indicates the maximum peak voltage value that may be applied to electrolytic capacitors during their application for a limited number of cycles.[A. Teverovsky, Perot Systems Code 562, NASA GSFCE, Effect of Surge Current Testing on Reliability of Solid Tantalum Capacitor]

ecadigitallibrary.com

Transient voltage

Aluminum electrolytic capacitors with non-solid electrolyte are relatively insensitive to high and short-term transient voltages higher than surge voltage, if the frequency and the energy content of the transients are low. This ability depends on rated voltage and component size. Low energy transient voltages lead to a voltage limitation similar to a zener diode

A Zener diode is a special type of diode designed to reliably allow current to flow "backwards" (inverted polarity) when a certain set reverse voltage, known as the ''Zener voltage'', is reached.

Zener diodes are manufactured with a great varie ...

. An unambiguous and general specification of tolerable transients or peak voltages is not possible. In every case transients arise, the application has to be approved very carefully.

Electrolytic capacitors with solid manganese oxide or polymer electrolyte, and aluminum as well as tantalum electrolytic capacitors cannot withstand transients or peak voltages higher than the surge voltage. Transients may destroy this type of electrolytic capacitor.

Reverse voltage

Standard electrolytic capacitors, and aluminum as well as tantalum and niobium electrolytic capacitors are polarized and generally require the anode electrode voltage to be positive relative to the cathode voltage.

Nevertheless, electrolytic capacitors can withstand for short instants a reverse voltage for a limited number of cycles. Specifically, aluminum electrolytic capacitors with non-solid electrolyte can withstand a reverse voltage of about 1 V to 1.5 V. This reverse voltage should never be used to determine the maximum reverse voltage under which a capacitor can be used permanently.

Standard electrolytic capacitors, and aluminum as well as tantalum and niobium electrolytic capacitors are polarized and generally require the anode electrode voltage to be positive relative to the cathode voltage.

Nevertheless, electrolytic capacitors can withstand for short instants a reverse voltage for a limited number of cycles. Specifically, aluminum electrolytic capacitors with non-solid electrolyte can withstand a reverse voltage of about 1 V to 1.5 V. This reverse voltage should never be used to determine the maximum reverse voltage under which a capacitor can be used permanently.[CDM Cornell Dubilier]

"Aluminum Electrolytic Capacitor Application Guide"

p. 4 and p. 6 and p. 9

Solid tantalum capacitors can also withstand reverse voltages for short periods. The most common guidelines for tantalum reverse voltage are:

*10 % of rated voltage to a maximum of 1 V at 25 °C,

*3 % of rated voltage to a maximum of 0.5 V at 85 °C,

*1 % of rated voltage to a maximum of 0.1 V at 125 °C.

These guidelines apply for short excursion and should never be used to determine the maximum reverse voltage under which a capacitor can be used permanently.

But in no case, for aluminum as well as for tantalum and niobium electrolytic capacitors, may a reverse voltage be used for a permanent AC application.

To minimize the likelihood of a polarized electrolytic being incorrectly inserted into a circuit, polarity has to be very clearly indicated on the case, see the section on polarity marking below.

Special bipolar aluminum electrolytic capacitors designed for bipolar operation are available, and usually referred to as "non-polarized" or "bipolar" types. In these, the capacitors have two anode foils with full-thickness oxide layers connected in reverse polarity. On the alternate halves of the AC cycles, one of the oxides on the foil acts as a blocking dielectric, preventing reverse current from damaging the electrolyte of the other one. But these bipolar electrolytic capacitors are not suitable for main AC applications instead of power capacitors with metallized polymer film or paper dielectric.

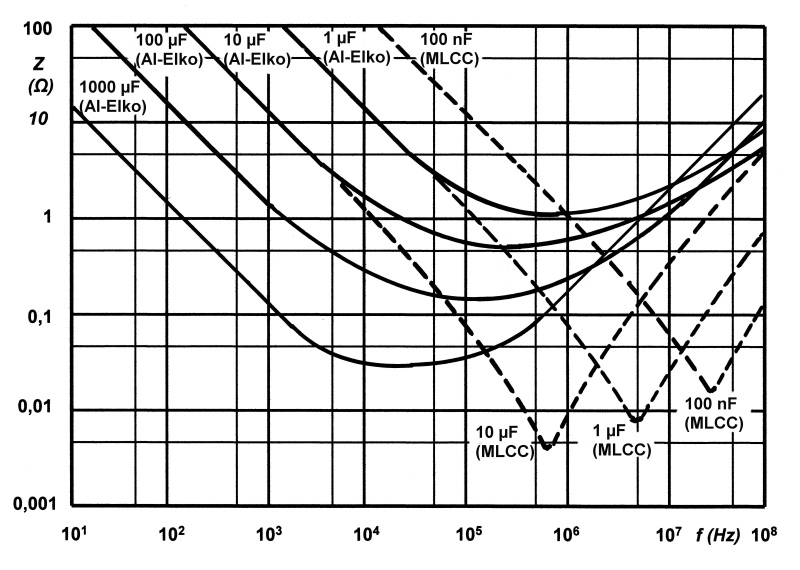

Impedance

In general, a capacitor is seen as a storage component for electric energy. But this is only one capacitor application. A capacitor can also act as an AC

In general, a capacitor is seen as a storage component for electric energy. But this is only one capacitor application. A capacitor can also act as an AC resistor

A resistor is a passive two-terminal electrical component that implements electrical resistance as a circuit element. In electronic circuits, resistors are used to reduce current flow, adjust signal levels, to divide voltages, bias active el ...

. Aluminum electrolytic capacitors in particular are often used as decoupling capacitor

A decoupling capacitor is a capacitor used to decouple one part of an electrical network (circuit) from another. Noise caused by other circuit elements is shunted through the capacitor, reducing its effect on the rest of the circuit. For hig ...

s to filter or bypass undesired AC frequencies to ground or for capacitive coupling

Capacitive coupling is the transfer of energy within an electrical network or between distant networks by means of displacement current between circuit(s) nodes, induced by the electric field. This coupling can have an intentional or accidental ...

of audio AC signals. Then the dielectric is used only for blocking DC. For such applications, the impedance (AC resistance) is as important as the capacitance value.

The impedance ''Z'' is the vector sum of reactance and resistance; it describes the phase difference and the ratio of amplitudes between sinusoidally varying voltage and sinusoidally varying current at a given frequency. In this sense impedance is a measure of the ability of the capacitor to pass alternating currents and can be used like Ohm's law.

:

In other words, impedance is a frequency-dependent AC resistance and possesses both magnitude and

The impedance ''Z'' is the vector sum of reactance and resistance; it describes the phase difference and the ratio of amplitudes between sinusoidally varying voltage and sinusoidally varying current at a given frequency. In this sense impedance is a measure of the ability of the capacitor to pass alternating currents and can be used like Ohm's law.

:

In other words, impedance is a frequency-dependent AC resistance and possesses both magnitude and phase

Phase or phases may refer to:

Science

*State of matter, or phase, one of the distinct forms in which matter can exist

*Phase (matter), a region of space throughout which all physical properties are essentially uniform

* Phase space, a mathematic ...

at a particular frequency.

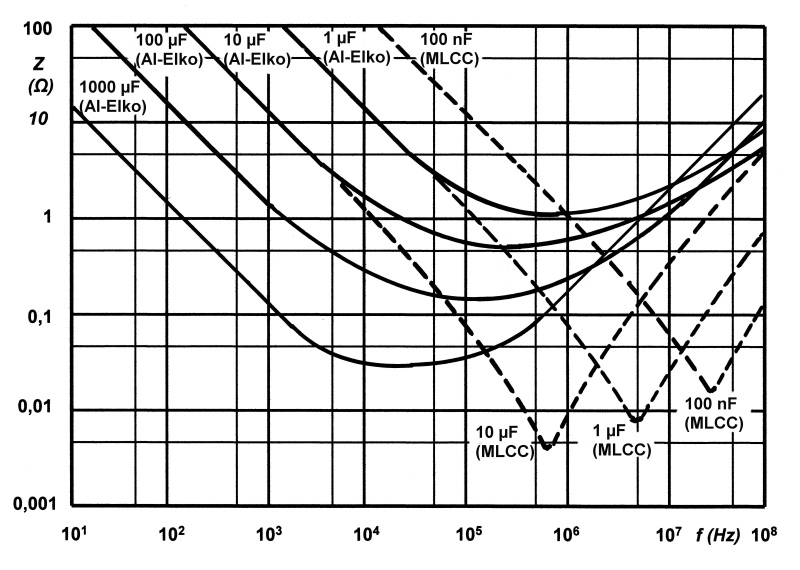

In data sheets of electrolytic capacitors only the impedance magnitude '', Z, '' is specified, and simply written as ''"Z".'' Regarding the IEC/EN 60384-1 standard, the impedance values of electrolytic capacitors are measured and specified at 10 kHz or 100 kHz depending on the capacitance and voltage of the capacitor.

Besides measuring, the impedance can be calculated using the idealized components of a capacitor's series-equivalent circuit, including an ideal capacitor ''C'', a resistor ''ESR'', and an inductance ''ESL''. In this case the impedance at the angular frequency ''ω'' is given by the geometric (complex) addition of ''ESR'', by a capacitive reactance ''XC''

:

and by an inductive reactance ''XL'' (Inductance

Inductance is the tendency of an electrical conductor to oppose a change in the electric current flowing through it. The flow of electric current creates a magnetic field around the conductor. The field strength depends on the magnitude of the ...

)

.

Then ''Z'' is given by

: .

In the special case of resonance

Resonance describes the phenomenon of increased amplitude that occurs when the frequency of an applied periodic force (or a Fourier component of it) is equal or close to a natural frequency of the system on which it acts. When an oscillatin ...

, in which the both reactive resistances ''XC'' and ''XL'' have the same value (''XC=XL''), then the impedance will only be determined by ''ESR''. With frequencies above the resonance the impedance increases again due to the ''ESL'' of the capacitor. The capacitor becomes an inductor.

ESR and dissipation factor tan δ

File:Elko-Impedanzverlauf-mit-ESR.svg, Typical impedance and ESR as a function of frequency

File:E-cap-impedance_versus_temperature.jpg, Typical impedance as a function of temperature

The equivalent series resistance

Practical capacitors and inductors as used in electric circuits are not ideal components with only capacitance or inductance. However, they can be treated, to a very good degree of approximation, as being ideal capacitors and inductors in series ...

(''ESR'') summarizes all resistive losses of the capacitor. These are the terminal resistances, the contact resistance of the electrode contact, the line resistance of the electrodes, the electrolyte resistance, and the dielectric losses in the dielectric oxide layer.

For electrolytic capacitors, ''ESR'' generally decreases with increasing frequency and temperature.ripple

Ripple may refer to:

Science and technology

* Capillary wave, commonly known as ripple, a wave traveling along the phase boundary of a fluid

** Ripple, more generally a disturbance, for example of spacetime in gravitational waves

* Ripple (electri ...

after smoothing and may influence the circuit functionality. Within the capacitor, ''ESR'' accounts for internal heat generation if a ripple current flows across the capacitor. This internal heat reduces the lifetime of non-solid aluminum electrolytic capacitors and affects the reliability of solid tantalum electrolytic capacitors.

For electrolytic capacitors, for historical reasons the dissipation factor In physics, the dissipation factor (DF) is a measure of loss-rate of energy of a mode of oscillation (mechanical, electrical, or electromechanical) in a dissipative system. It is the reciprocal of quality factor, which represents the "quality" or d ...

''tan δ'' will sometimes be specified in the data sheet instead of the ''ESR''. The dissipation factor is determined by the tangent of the phase angle between the capacitive reactance ''XC'' minus the inductive reactance ''XL'' and the ''ESR''. If the inductance ''ESL'' is small, the dissipation factor can be approximated as:

:

The dissipation factor is used for capacitors with very low losses in frequency-determining circuits where the reciprocal value of the dissipation factor is called the quality factor

In physics and engineering, the quality factor or ''Q'' factor is a dimensionless parameter that describes how underdamped an oscillator or resonator is. It is defined as the ratio of the initial energy stored in the resonator to the energy los ...

(Q), which represents a resonator's bandwidth

Bandwidth commonly refers to:

* Bandwidth (signal processing) or ''analog bandwidth'', ''frequency bandwidth'', or ''radio bandwidth'', a measure of the width of a frequency range

* Bandwidth (computing), the rate of data transfer, bit rate or thr ...

.

Ripple current

"Ripple current" is the RMS value of a superimposed AC current of any frequency and any waveform of the current curve for continuous operation within the specified temperature range. It arises mainly in power supplies (including

"Ripple current" is the RMS value of a superimposed AC current of any frequency and any waveform of the current curve for continuous operation within the specified temperature range. It arises mainly in power supplies (including switched-mode power supplies

A switched-mode power supply (switching-mode power supply, switch-mode power supply, switched power supply, SMPS, or switcher) is an electronic power supply that incorporates a switching regulator to convert electrical power efficiently.

Like ...

) after rectifying an AC voltage and flows as charge and discharge current through any decoupling and smoothing capacitors.

Ripple currents generate heat inside the capacitor body. This dissipation power loss ''PL'' is caused by ''ESR'' and is the squared value of the effective (RMS) ripple current ''IR''.

:

This internally generated heat, additional to the ambient temperature and possibly other external heat sources, leads to a capacitor body temperature having a temperature difference of ''Δ T'' relative to ambient. This heat has to be distributed as thermal losses ''Pth'' over the capacitor's surface ''A'' and the thermal resistance ''β'' to ambient.

:

The internally generated heat has to be distributed to ambient by thermal radiation

Thermal radiation is electromagnetic radiation generated by the thermal motion of particles in matter. Thermal radiation is generated when heat from the movement of charges in the material (electrons and protons in common forms of matter) is ...

, convection

Convection is single or multiphase fluid flow that occurs spontaneously due to the combined effects of material property heterogeneity and body forces on a fluid, most commonly density and gravity (see buoyancy). When the cause of the convec ...

, and thermal conduction. The temperature of the capacitor, which is the net difference between heat produced and heat dissipated, must not exceed the capacitor's maximum specified temperature.

The ripple current is specified as an effective (RMS) value at 100 or 120 Hz or at 10 kHz at upper category temperature. Non-sinusoidal ripple currents have to be analyzed and separated into their single sinusoidal frequencies by means of Fourier analysis

In mathematics, Fourier analysis () is the study of the way general functions may be represented or approximated by sums of simpler trigonometric functions. Fourier analysis grew from the study of Fourier series, and is named after Josep ...

and summarized by squared addition the single currents.

Current surge, peak or pulse current

Aluminum electrolytic capacitors with non-solid electrolytes normally can be charged up to the rated voltage without any current surge, peak or pulse limitation. This property is a result of the limited ion movability in the liquid electrolyte, which slows down the voltage ramp across the dielectric, and of the capacitor's ESR. Only the frequency of peaks integrated over time must not exceed the maximal specified ripple current.

Solid tantalum electrolytic capacitors with manganese dioxide electrolyte or polymer electrolyte are damaged by peak or pulse currents.

Leakage current

For electrolytic capacitors, DC leakage current (DCL) is a special characteristic that other conventional capacitors do not have. This current is represented by the resistor Rleak in parallel with the capacitor in the series-equivalent circuit of electrolytic capacitors.

The reasons for leakage current are different between electrolytic capacitors with non-solid and with solid electrolyte or more common for "wet" aluminum and for "solid" tantalum electrolytic capacitors with manganese dioxide electrolyte as well as for electrolytic capacitors with polymer electrolytes. For non-solid aluminum electrolytic capacitors the leakage current includes all weakened imperfections of the dielectric caused by unwanted chemical processes taking place during the time without applied voltage (storage time) between operating cycles. These unwanted chemical processes depend on the kind of electrolyte. Water-based electrolytes are more aggressive to the aluminum oxide layer than are electrolytes based on organic liquids. This is why different electrolytic capacitor series specify different storage time without reforming.

Applying a positive voltage to a "wet" capacitor causes a reforming (self-healing) process which repairs all weakened dielectric layers, and the leakage current remain at a low level.

For electrolytic capacitors, DC leakage current (DCL) is a special characteristic that other conventional capacitors do not have. This current is represented by the resistor Rleak in parallel with the capacitor in the series-equivalent circuit of electrolytic capacitors.

The reasons for leakage current are different between electrolytic capacitors with non-solid and with solid electrolyte or more common for "wet" aluminum and for "solid" tantalum electrolytic capacitors with manganese dioxide electrolyte as well as for electrolytic capacitors with polymer electrolytes. For non-solid aluminum electrolytic capacitors the leakage current includes all weakened imperfections of the dielectric caused by unwanted chemical processes taking place during the time without applied voltage (storage time) between operating cycles. These unwanted chemical processes depend on the kind of electrolyte. Water-based electrolytes are more aggressive to the aluminum oxide layer than are electrolytes based on organic liquids. This is why different electrolytic capacitor series specify different storage time without reforming.

Applying a positive voltage to a "wet" capacitor causes a reforming (self-healing) process which repairs all weakened dielectric layers, and the leakage current remain at a low level.[Ch. Baur, N. Will, Epcos, Long-term stability of aluminum electrolytic capacitor]

Built to last

Although the leakage current of non-solid electrolytic capacitors is higher than current flow across the dielectric in ceramic or film capacitors, self-discharge of modern non-solid electrolytic capacitors with organic electrolytes takes several weeks.

The main causes of DCL for solid tantalum capacitors include electrical breakdown of the dielectric; conductive paths due to impurities or poor anodization; and bypassing of dielectric due to excess manganese dioxide, to moisture paths, or to cathode conductors (carbon, silver). This "normal" leakage current in solid electrolyte capacitors cannot be reduced by "healing", because under normal conditions solid electrolytes cannot provide oxygen for forming processes. This statement should not be confused with the self-healing process during field crystallization, see below, Reliability (Failure rate).

The specification of the leakage current in data sheets is often given as multiplication of the rated capacitance value ''CR'' with the value of the rated voltage ''UR'' together with an addendum figure, measured after a measuring time of 2 or 5 minutes, for example:

:

The leakage current value depends on the voltage applied, on the temperature of the capacitor, and on measuring time. Leakage current in solid MnO2 tantalum electrolytic capacitors generally drops very much faster than for non-solid electrolytic capacitors but remain at the level reached.

Dielectric absorption (soakage)

Dielectric absorption occurs when a capacitor that has remained charged for a long time discharges only incompletely when briefly discharged. Although an ideal capacitor would reach zero volts after discharge, real capacitors develop a small voltage from time-delayed dipole discharging, a phenomenon that is also called dielectric relaxation

In electromagnetism, a dielectric (or dielectric medium) is an electrical insulator that can be polarised by an applied electric field. When a dielectric material is placed in an electric field, electric charges do not flow through the mater ...

, "soakage" or "battery action".

Dielectric absorption may be a problem in circuits where very small currents are used in the function of an electronic circuit, such as long- time-constant integrator

An integrator in measurement and control applications is an element whose output signal is the time integral of its input signal. It accumulates the input quantity over a defined time to produce a representative output.

Integration is an importan ...

s or sample-and-hold

In electronics, a sample and hold (also known as sample and follow) circuit is an analog device that samples (captures, takes) the voltage of a continuously varying analog signal and holds (locks, freezes) its value at a constant level for a ...

circuits. In most electrolytic capacitor applications supporting power supply lines, dielectric absorption is not a problem.

But especially for electrolytic capacitors with high rated voltage, the voltage at the terminals generated by the dielectric absorption can pose a safety risk to personnel or circuits. In order to prevent shocks, most very large capacitors are shipped with shorting wires that need to be removed before the capacitors are used.

Operational characteristics

Reliability (failure rate)

The

The reliability

Reliability, reliable, or unreliable may refer to:

Science, technology, and mathematics Computing

* Data reliability (disambiguation), a property of some disk arrays in computer storage

* High availability

* Reliability (computer networking), a ...

of a component is a property that indicates how reliably this component performs its function in a time interval. It is subject to a stochastic process

In probability theory and related fields, a stochastic () or random process is a mathematical object usually defined as a family of random variables. Stochastic processes are widely used as mathematical models of systems and phenomena that appea ...

and can be described qualitatively and quantitatively; it is not directly measurable. The reliability of electrolytic capacitors is empirically determined by identifying the failure rate

Failure rate is the frequency with which an engineered system or component fails, expressed in failures per unit of time. It is usually denoted by the Greek letter λ (lambda) and is often used in reliability engineering.

The failure rate of a ...

in production accompanying endurance tests, see Reliability engineering

Reliability engineering is a sub-discipline of systems engineering that emphasizes the ability of equipment to function without failure. Reliability describes the ability of a system or component to function under stated conditions for a specifie ...

.

Reliability normally is shown as a bathtub curve

The bathtub curve is widely used in reliability engineering and deterioration modeling. It describes a particular form of the hazard function which comprises three parts:

*The first part is a decreasing failure rate, known as early failures.

*Th ...

and is divided into three areas: early failures or infant mortality failures, constant random failures and wear out failures. Failures totalized in a failure rate are short circuit, open circuit, and degradation failures (exceeding electrical parameters).

The reliability

Reliability, reliable, or unreliable may refer to:

Science, technology, and mathematics Computing

* Data reliability (disambiguation), a property of some disk arrays in computer storage

* High availability

* Reliability (computer networking), a ...

prediction is generally expressed in a failure rate

Failure rate is the frequency with which an engineered system or component fails, expressed in failures per unit of time. It is usually denoted by the Greek letter λ (lambda) and is often used in reliability engineering.

The failure rate of a ...

λ, abbreviated FIT (Failures In Time). This is the number of failures that can be expected in one billion (109) component-hours of operation (e.g., 1000 components for 1 million hours, or 1 million components for 1000 hours which is 1 ppm/1000 hours) at fixed working conditions during the period of constant random failures. This failure rate model implicitly assumes the idea of "random failure". Individual components fail at random times but at a predictable rate.

Billion

Billion is a word for a large number, and it has two distinct definitions:

*1,000,000,000, i.e. one thousand million, or (ten to the ninth power), as defined on the short scale. This is its only current meaning in English.

* 1,000,000,000,000, i. ...

s of tested capacitor unit-hours would be needed to establish failure rates in the very low level range which are required today to ensure the production of large quantities of components without failures. This requires about a million units over a long time period, which means a large staff and considerable financing. The tested failure rates are often complemented with figures resulting from feedback from the field from major customers (field failure rate), which mostly results in a lower failure rate than tested.

The reciprocal value of FIT is Mean Time Between Failures

Mean time between failures (MTBF) is the predicted elapsed time between inherent failures of a mechanical or electronic system during normal system operation. MTBF can be calculated as the arithmetic mean (average) time between failures of a system ...

(MTBF).

The standard operating conditions for FIT testing are 40 °C and 0.5 UR. For other conditions of applied voltage, current load, temperature, capacitance value, circuit resistance (for tantalum capacitors), mechanical influences and humidity, the FIT figure can be converted with acceleration factors standardized for industrial or military applications. The higher the temperature and applied voltage, the higher the failure rate, for example.